Refractory

Process

Today, refractory materials are used in industries worldwide to confine heat and increase thermal efficiency. As they are resistant to decomposition by heat, pressure, or chemical attack, they are best suited for boiler furnaces, kilns, ducts, incinerators, and reactors to temperatures up to 1,000 °F (811 K; 538 °C).

Refractory can be applied by casting or gunning method. Gunning method is a flexible approach and fast-paced compared to conventional castables with no need for shuttering or vibrators.

Application

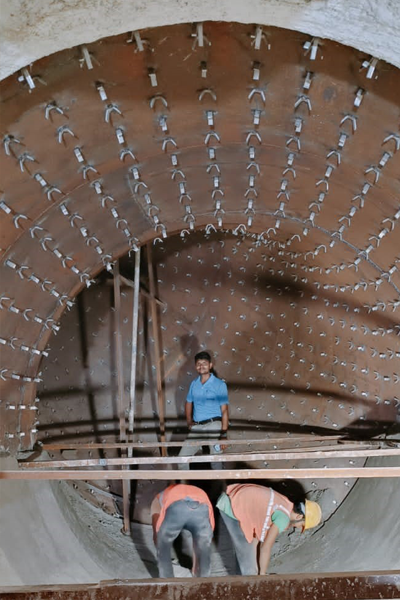

Our expert technical team would arrive with all the necessary tools and types of machinery from our head office. Post joint inspection, the team will mark and break the old refractory. Use appropriate refractory anchors to hold and secure the Refractory.

If gunning method is preferred, our team will use the gunning machine maintaining the customers requested thickness and provide a smooth application of refractory capacity of around 20-25 tons per day.

For the Castable method, post-material preparation (using a mixture machine), Farma is prepared and shuttering fixed. Once ready, Castable refractory is applied to maintain the customers requested thickness and can achieve a capacity of around 8-10 tons per day.